Weather-Sealing Strategies That Define a High-Quality Powersports Amplifier

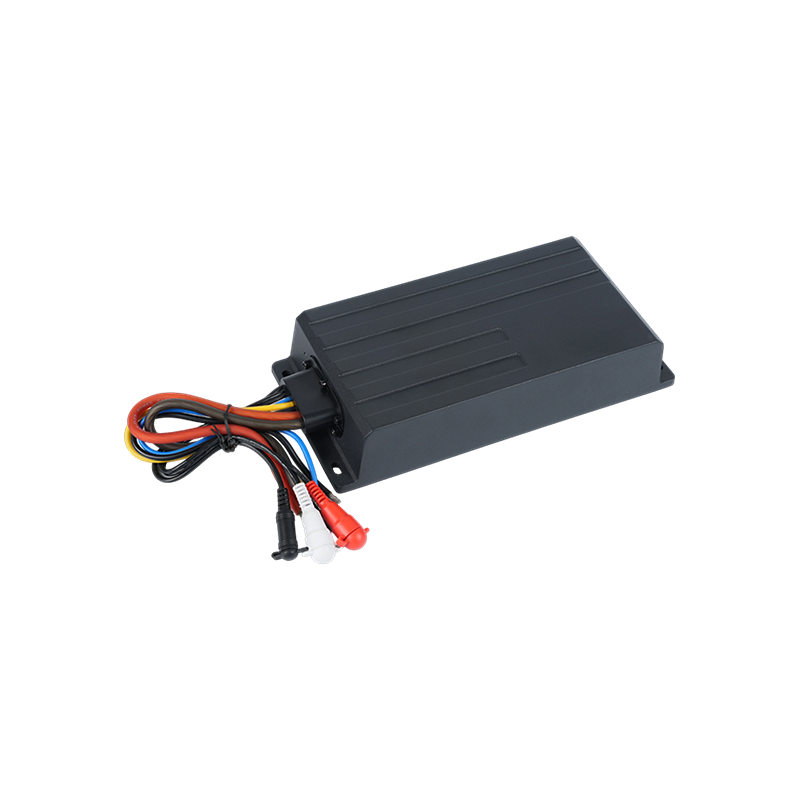

Unlike automotive amplifiers, powersports amps must withstand continuous exposure to moisture, mud, UV radiation, and salt spray. To achieve this, engineers use conformal-coated PCBs, waterproof gaskets around terminal ports, and resin-encapsulated inductors to prevent corrosion. Potting compounds may also be used for the most sensitive areas, adding mechanical stability while blocking water intrusion. In advanced manufacturing facilities like Newsources, AOI inspection and aging tests are critical to ensuring every sealed component remains reliable under harsh weather fluctuations typical of off-road environments.

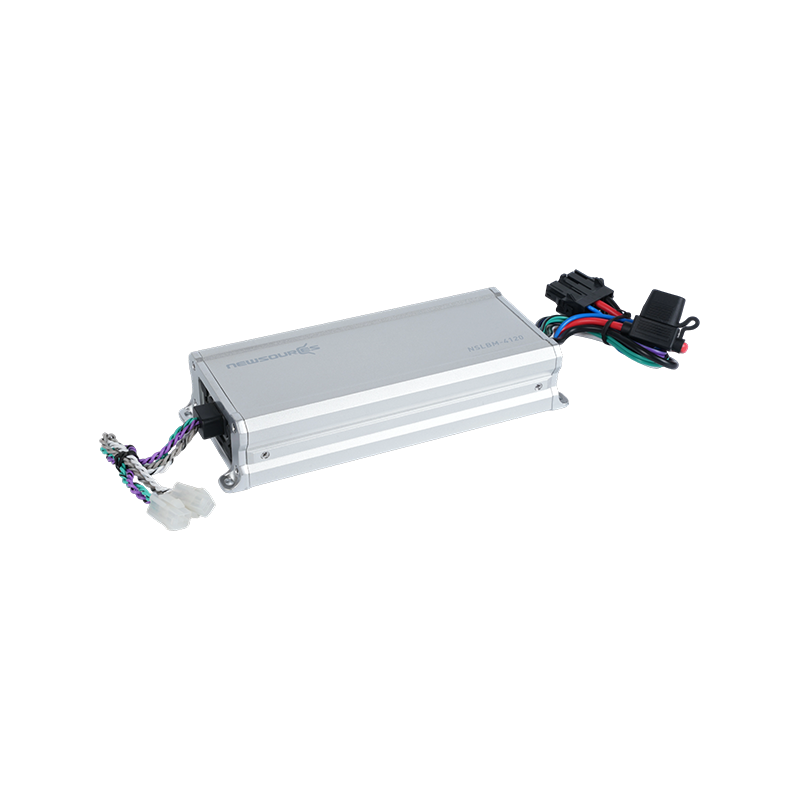

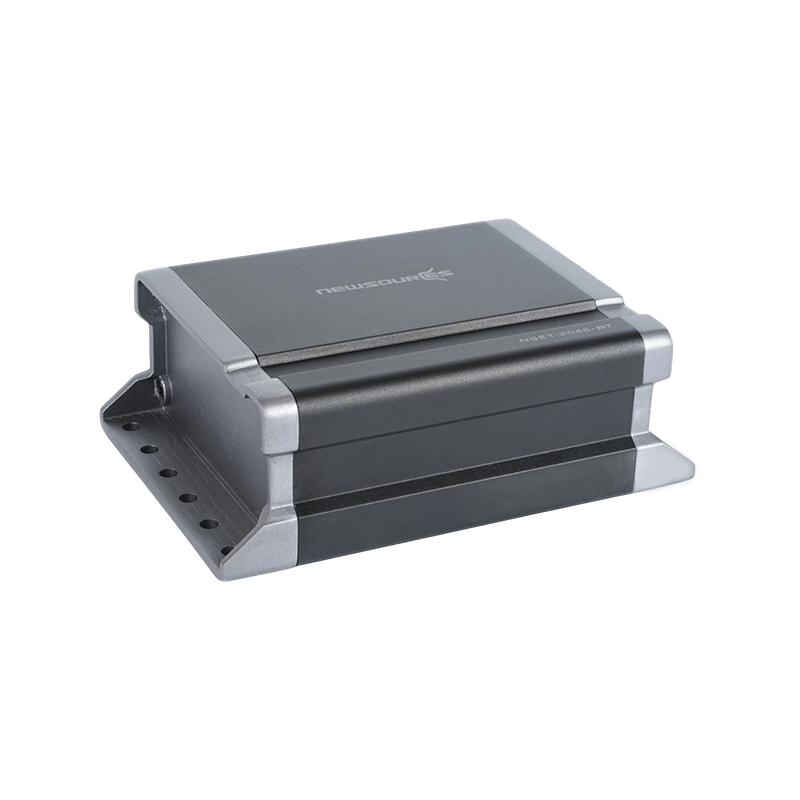

How Vibrational Forces Impact Powersports Amplifier Reliability

Motorcycles, ATVs, and UTVs generate significantly higher levels of vibration than automotive cabins, impacting solder joints, connectors, and capacitors inside a powersports amplifier. Engineers counter this by using thicker PCB substrates, SMT components with stronger adhesion, and reinforced mounting brackets. Extra attention is also given to connector selection—locking or compression-style terminals ensure that wiring remains stable even when the vehicle is driven aggressively over uneven terrain. A well-built amplifier undergoes vibration simulation equivalent to years of real-world use before being approved for production.

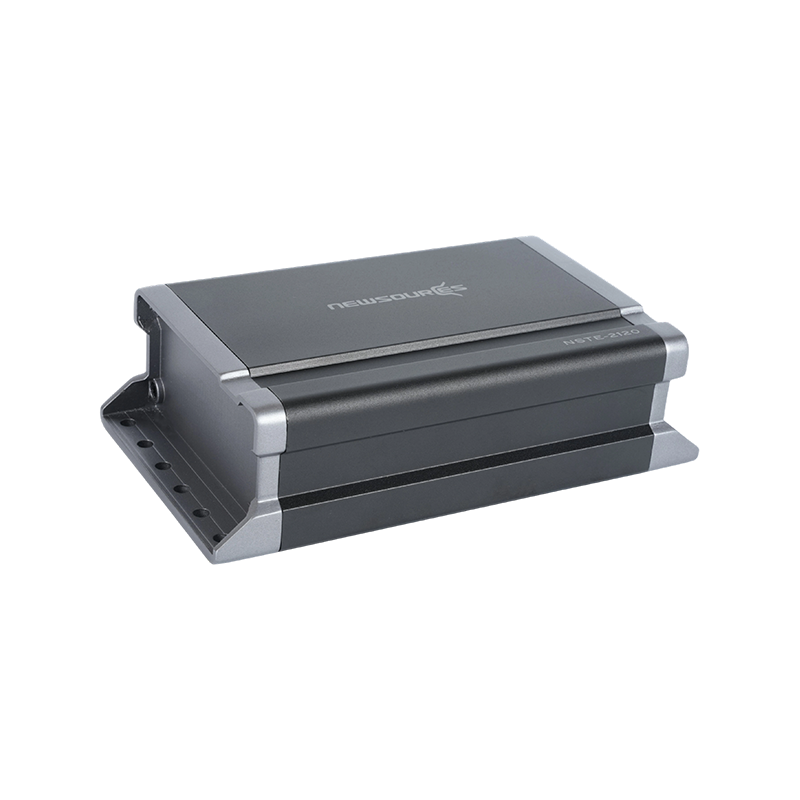

Heat Management in Open-Air Powersports Installations

While open-air mounting allows better natural airflow, powersports amplifiers still face thermal challenges due to direct sunlight, high engine temperatures, and the lack of enclosed cabin cooling. Heat sinks with high surface area, thermally efficient MOSFETs, and advanced thermal throttling algorithms help prevent overheating. Engineers may also design enclosures in lighter colors to reduce surface heat absorption. During manufacturing, AP testing and stress aging cycles help confirm that the amplifier can deliver stable power without thermal collapse in outdoor environments.

Power Delivery Characteristics Optimized for Powersports Vehicles

Electrical systems in motorcycles and UTVs often experience rapid voltage fluctuations, especially during acceleration or heavy accessory load. To maintain stable output, a Powersport Amplifier typically incorporates wide-voltage power supplies, fast-reacting protection circuits, and input filters that smooth irregular battery profiles. Below is a comparison of techniques commonly used to stabilize power delivery in powersports audio systems:

| Stabilization Method |

Key Benefit |

Usage in Powersports Amps |

| Wide-Voltage SMPS |

Handles rapid voltage swings |

Highly common |

| Fast Protection Circuits |

Prevents damage during spikes |

Standard feature |

| Input Ripple Filters |

Smooths battery noise |

Often combined with SMPS |

Design Considerations for Audio Clarity in Noisy Riding Environments

Because powersports vehicles operate in extremely noisy conditions dominated by wind, engine, and road noise, amplifier tuning emphasizes midrange clarity and dynamic headroom rather than low-bass extension. Many systems boost frequencies around 1–4 kHz to enhance vocal presence and ensure music remains audible at high speeds. Engineers may also design amplifiers with high damping factors to maintain strong control over compact, weatherproof speakers commonly used in these applications. DSP integration, when available, allows fine adjustments tailored to different riding conditions.

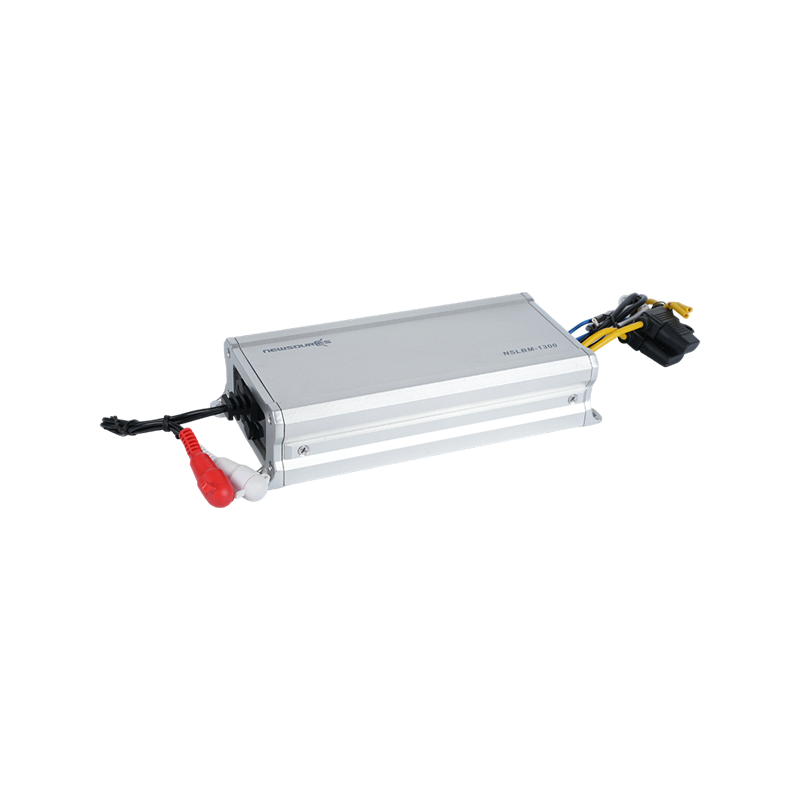

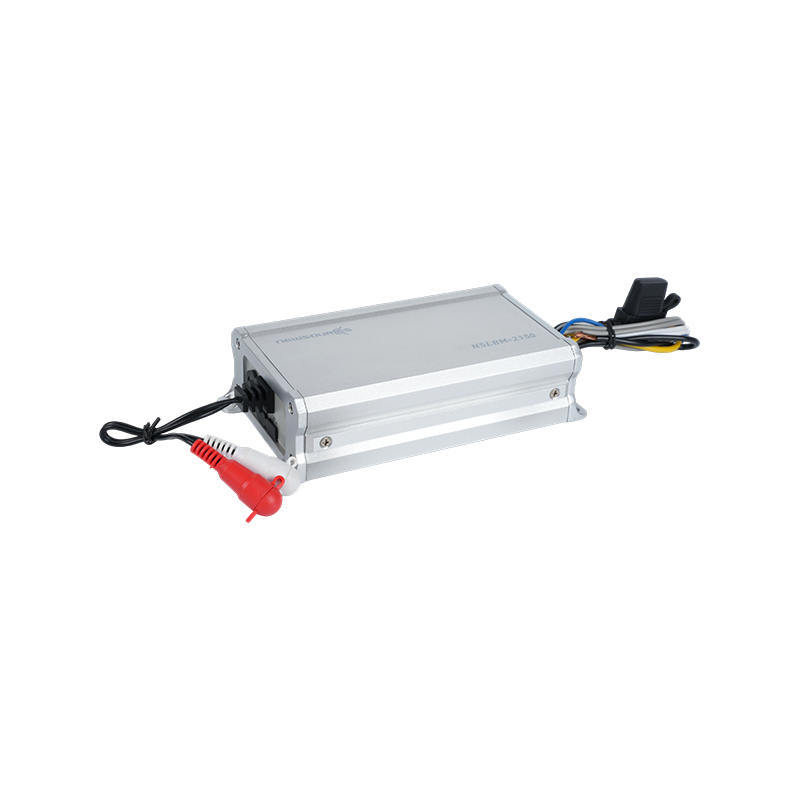

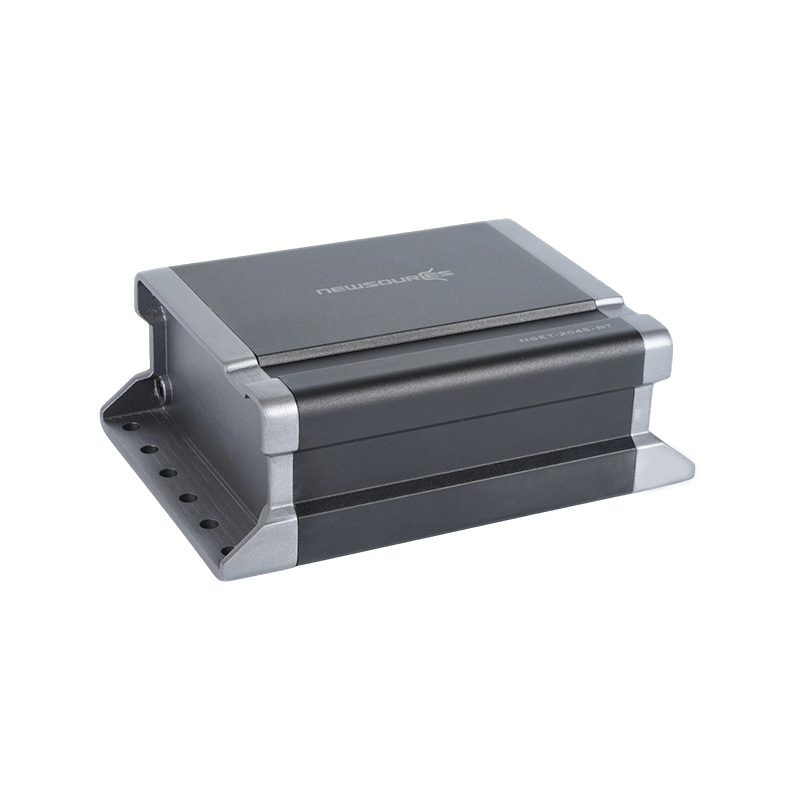

Mounting and Wiring Practices That Improve Longevity in Outdoor Applications

Proper mounting plays a major role in extending the life of a powersports amplifier. The ideal mounting surface is rigid, elevated from water pathways, and shielded from direct exhaust heat. All wiring should be marine-grade or OFC with UV-resistant jackets. Heat-shrink tubing, waterproof Deutsch connectors, and secured cable routing prevent moisture intrusion and wire fatigue. These installation practices, combined with manufacturing quality—such as SMT precision and 100% aging tests—ensure long-term reliability even in the most demanding off-road conditions.

EN

EN

English

English Español

Español عربى

عربى

.jpg)

.jpg)