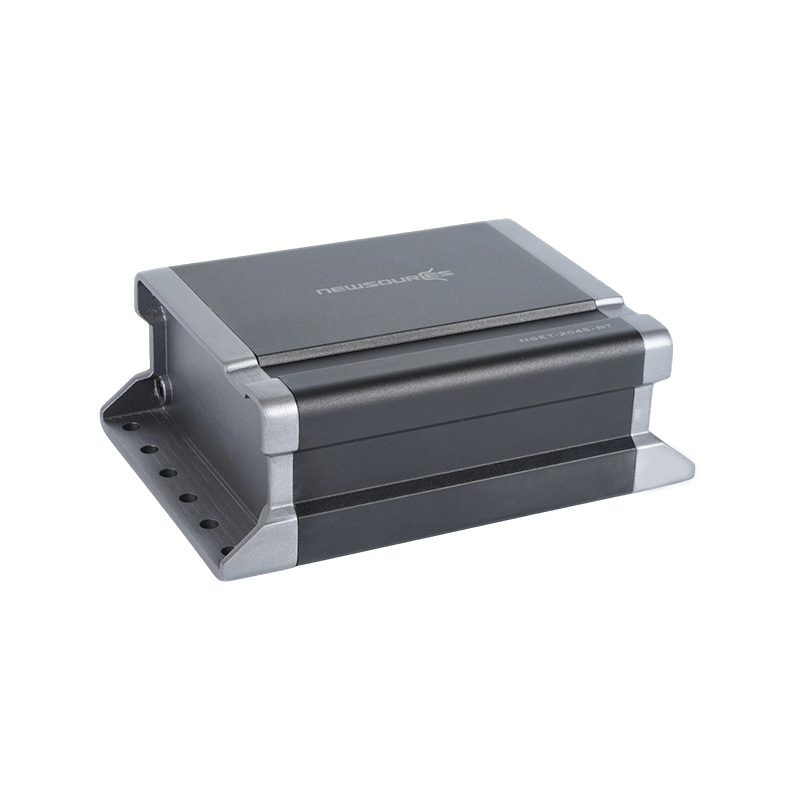

Thermal efficiency and placement tips for Class D Bluetooth Amplifiers

Class D Bluetooth Amplifiers deliver high electrical efficiency, which shrinks heat generation compared with linear designs, but thermal design still matters in vehicle installations. When integrating a compact Class D module into a car or marine environment, focus on conductive paths from power MOSFETs and output stages to the metal housing, use thermally conductive gap pads where direct screw mounting is possible, and maintain modest airflow around the housing. These steps reduce thermal throttling during long listening sessions and extend component life in real-world use.

Practical mounting checklist

- Mount the amplifier with the PCB-facing surface contacting a thermal plate or die-cast heatsink when possible to lower junction temperatures.

- Allow 10–20 mm clearance around the unit for convective flow, especially near head-unit and battery compartments.

- Use vibration-damping hardware at anchor points to protect solder joints and connectors under continuous road or trail vibration.

Wireless integration strategies for Bluetooth Car Audio Amplifiers

Bluetooth Car Audio Amplifiers provide convenient device streaming, but system behavior depends on auto-switching, priority signals, and input sensitivity. Implement signal-sensing logic that prefers the aftermarket head unit only when a wired input is present, and ensure the Bluetooth module supports stable reconnection after power cycles. For mixed-source systems, provide a clear priority map and user-accessible override so riders can switch seamlessly between Bluetooth source and factory head unit audio without pops or unexpected mute events.

User-experience considerations

- Implement brief mute/unmute ramps when switching sources to avoid audible clicks.

- Expose Bluetooth pairing reset via an accessible service pin or discreet button for dealer servicing.

- Provide clear LED status indicators or diagnostic codes for connection, pairing, and fault states to speed troubleshooting.

Ingress protection and real-world use of Waterproof Bluetooth Amplifiers

Achieving IPX4 or IPX5 performance requires attention to connector sealing, conformal coating selection, and harness routing. Waterproof Bluetooth Amplifiers often combine sealed external connectors with water-resistant PCB coatings rather than full potting, which preserves repairability. When specifying for marine or exposed-vehicle applications, require per-unit sealing validation and salt-fog resistant finishes on external metal surfaces to avoid premature corrosion that can compromise the seal over time.

Selection criteria for exposed environments

- Prefer sealed multi-pin connectors with replaceable gaskets to enable future harness replacement.

- Specify conformal coatings that resist salt, UV and thermal cycling while allowing selective rework when necessary.

- Require verification tests such as immersion, spray, and pressure-decay as part of acceptance criteria for Waterproof Bluetooth Amplifiers.

Protection circuits and reliability features in Bluetooth Car Amplifiers

Modern Bluetooth Car Amplifiers include short-circuit, thermal, and overload protection to safeguard both the amplifier and connected speakers. Design these safeguards to be fault-tolerant: thermal protection should gently reduce gain instead of abrupt shutdown, and short-circuit detection should provide latched retry logic with clear diagnostic output. These behaviors minimize nuisance failures while protecting hardware during real-world misuse or wiring faults.

Recommended protection behavior

| Protection |

Expected Response |

| Short-circuit |

Current limit and retry with LED fault indication |

| Thermal |

Graceful gain reduction, then restore after cooldown |

| Overload |

Foldback or speaker protection to prevent cone damage |

Manufacturing and QA practices that improve Bluetooth Car Audio Amplifiers consistency

Consistency in Bluetooth Car Audio Amplifiers depends on controlled production steps: automated SMT placement, inline optical inspection, wave solder control, and 100% functional aging to reveal early-life defects. Suppliers that integrate harness assembly and per-unit sealing checks reduce the risk of field moisture ingress. Partnering with a manufacturer that documents these processes and provides traceability for batches ensures predictable product behavior across hundreds or thousands of units.

When specifying Class D Bluetooth Amplifiers or Bluetooth Car Amplifiers for OEM or high-volume aftermarket programs, require thermal management plans, clear behavior for protection circuits, and production evidence of sealing and electrical aging. These practical measures — combined with thoughtful user-facing features such as stable source prioritization and accessible service points — produce Bluetooth Car Audio Amplifiers that offer efficient performance and reliable wireless streaming in everyday driving and challenging environments.

EN

EN

English

English Español

Español عربى

عربى

.jpg)

.jpg)