Connector and harness strategies that speed OE integration for Motorcycle Amplifiers

Using a consolidated TE-style connector approach simplifies wiring on crowded motorcycle platforms and reduces installation mistakes. For SEMI-OE Amplifiers intended to fit multiple bike models, build a short sealed pigtail with a universal TE plug at the amp end and offer vehicle-specific adapter leads. This lets technicians plug the amplifier into existing factory harnesses without cutting or re-crimping, while maintaining a replaceable sealing interface at the amplifier. The result: faster assembly, fewer returns, and a cleaner service workflow for Motorcycle Audio Amplifiers programs.

Practical harness features to demand from suppliers

- Color-coded, pre-terminated conductors with printed labels to reduce field diagnosis time for the Motorcycle Amp installers.

- Molded strain relief and replaceable gaskets at the connector to preserve IP sealing after service.

- Provision for an inline fuse and keyed power lead to prevent polarity and overcurrent errors during assembly.

Balancing water resistance and maintainability for Motorcycle Audio Amplifiers

Conformal coating on the PCB paired with sealed connectors often delivers sufficient protection for riding conditions without resorting to full potting, which complicates repairs. For SEMI-OE Amplifiers intended for consumer service or limited dealer repair, choose coatings rated for salt-fog and thermal cycling and design the connector seal to be user-replaceable. This preserves serviceability while meeting the moisture resistance standards expected for Motorcycle Amplifiers used in open-air environments.

Service-oriented sealing checklist

- Replaceable connector gaskets with documented part numbers to allow quick field repairs.

- Coating processes that permit rework (selective masking during conformal coating) to avoid full-module replacement.

- Clear instructions for cleaning and re-sealing connector interfaces after crash or water exposure.

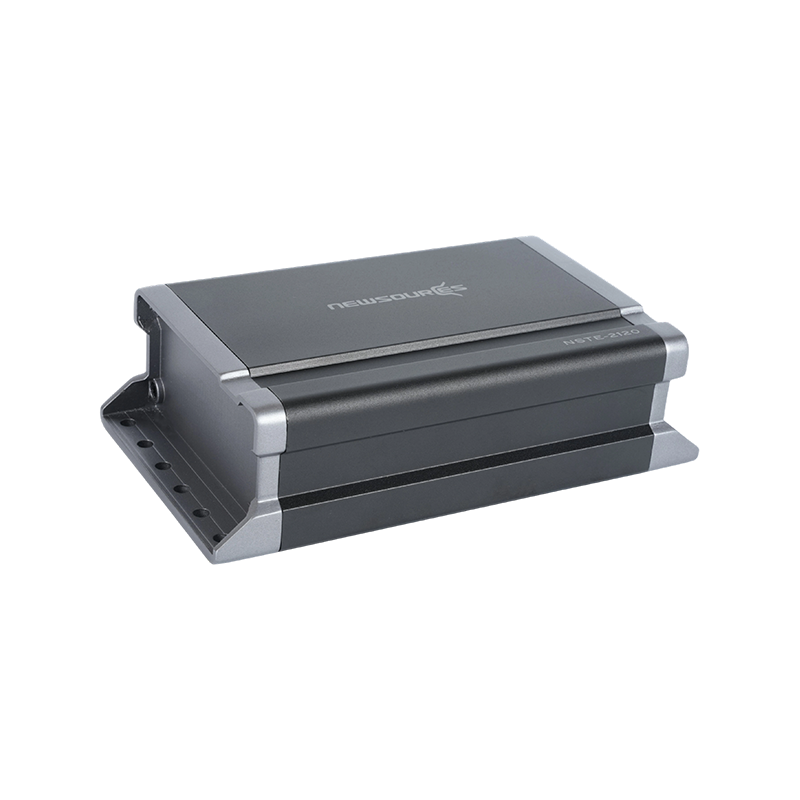

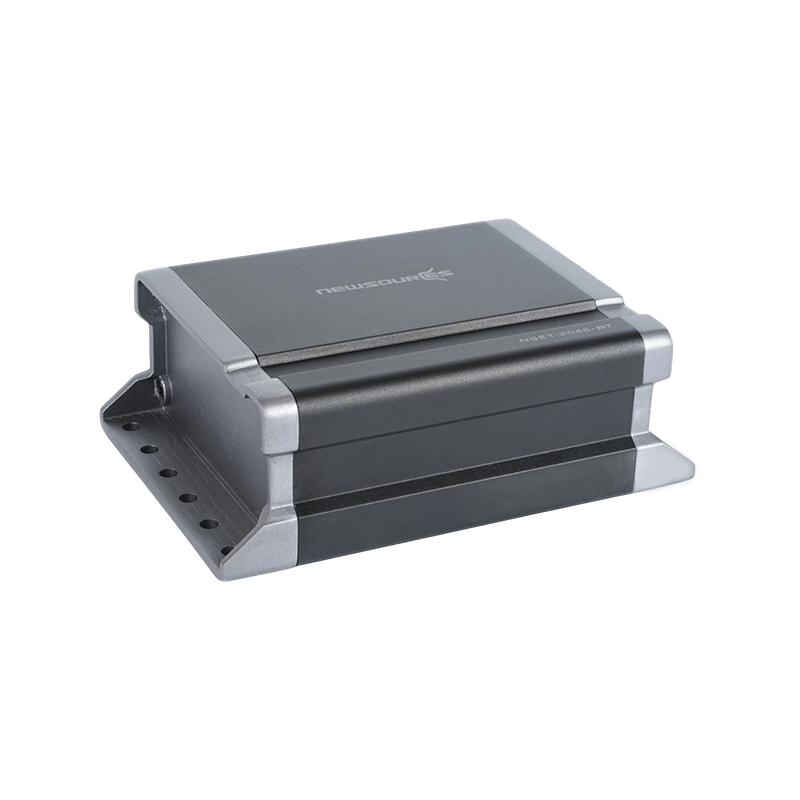

Thermal design and mounting guidance for compact motorcycle installations

Class D efficiency reduces dissipation, yet heat concentration remains critical in tight enclosures. When specifying a Motorcycle Amp for seat- or tail-mounted installations, require thermal interface elements that transfer PCB heat to the die-cast housing, and avoid fully enclosed cavities without some convective path. Even modest clearances and conductive mounting pads materially extend component lifetime and limit thermal throttling during extended rides.

Quick mounting rules for field reliability

- Rubber-isolated fasteners to decouple vibration from solder joints and connectors.

- Minimum clearance of 10–15 mm around the housing to allow airflow and reduce heat soak.

- Separate routing for power and signal harnesses to lower EMI and noise pickup in Motorcycle Audio Amplifiers systems.

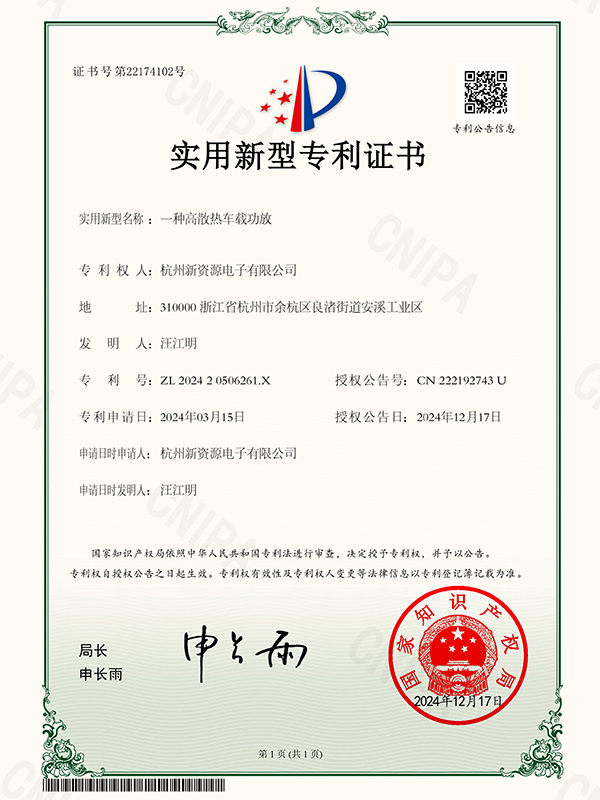

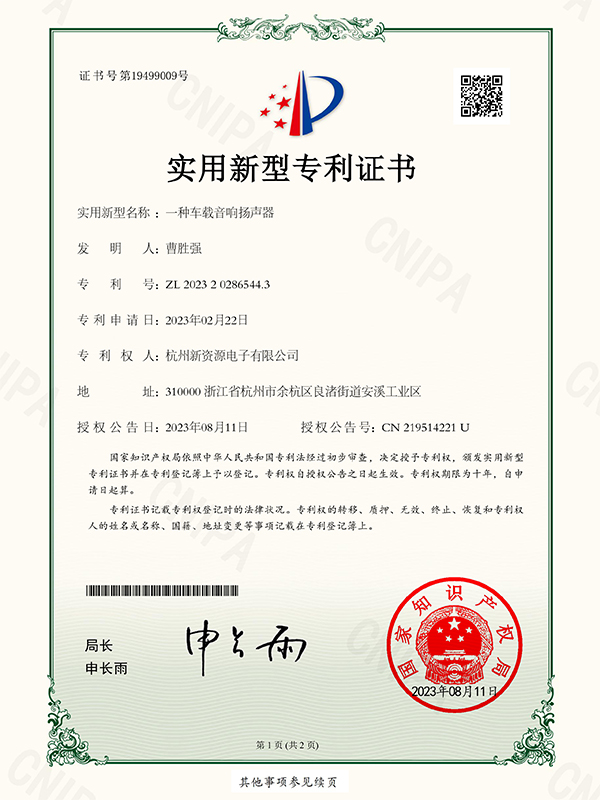

Manufacturing and QA practices that support dependable SEMI-OE Amplifiers supply

A supplier that combines modern surface-mount lines, automated optical inspection, and thorough functional aging will consistently deliver lower field-failure rates. For Motorcycle Amplifiers and SEMI-OE Amplifiers, insist on per-unit electrical verification after harness assembly and a sealing validation step — such as air-leak or pressure-decay testing — to confirm each unit meets the specified ingress protection after final assembly.

Production capabilities to verify when qualifying a partner

| Capability |

Reason to check |

| SMT assembly and AOI |

Ensures reproducible, high-density PCB builds for modern Motorcycle Audio Amplifiers. |

| 100% functional aging |

Catches infant mortality and confirms stability under load prior to shipment. |

| Per-unit sealing verification |

Validates the actual installed harness and connector seals on each Motorcycle Amp. |

Installer and OEM considerations for product launch and aftersales

When moving from prototype to production for Motorcycle Amplifiers or SEMI-OE Amplifiers, prepare clear kit contents, adapter harness SKUs, and a service parts list for common motorcycle models. Include installation diagrams that show connector orientation, harness exit direction, and torque or pull limits for connector fastenings. These small documents reduce warranty cycles and make dealer-level repairs faster and more consistent.

By combining modular TE-style connectors, targeted conformal coatings, thermal interface design, and supplier processes that include SMT, AOI, and per-unit aging/sealing checks, OEMs and aftermarket brands can deploy robust Motorcycle Audio Amplifiers that meet space and durability constraints. Thoughtful design and production control make the difference between a nominal product and a field-proven Motorcycle Amp that performs reliably through years of riding and exposure.

EN

EN

English

English Español

Español عربى

عربى

.jpg)

.jpg)