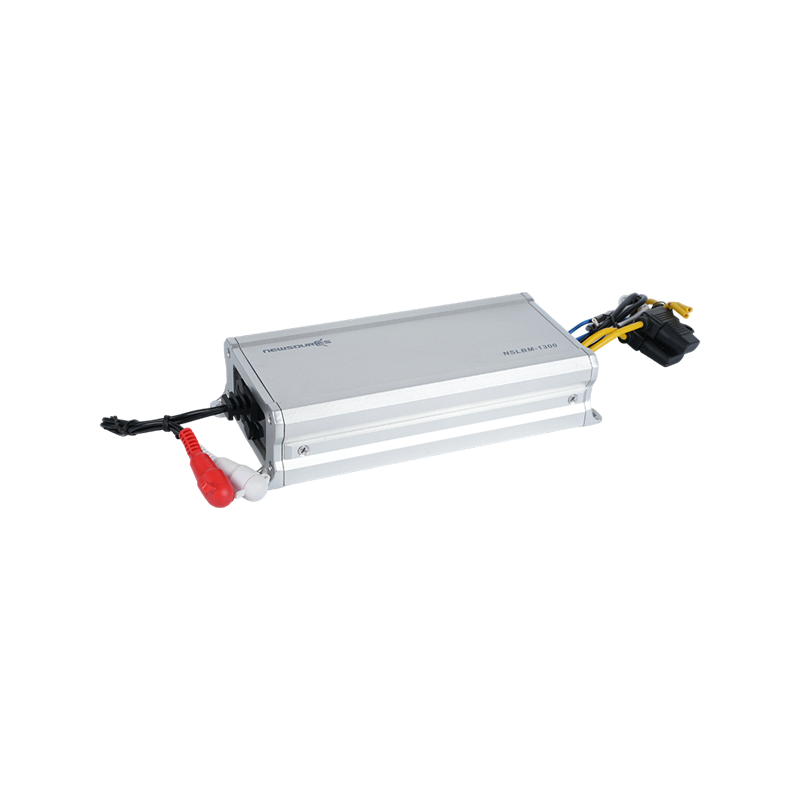

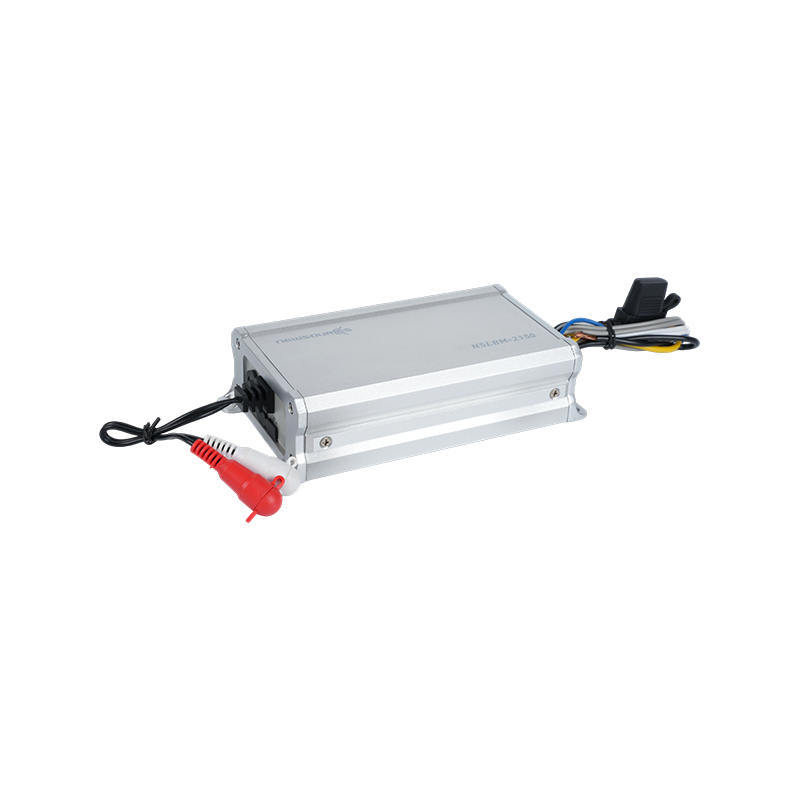

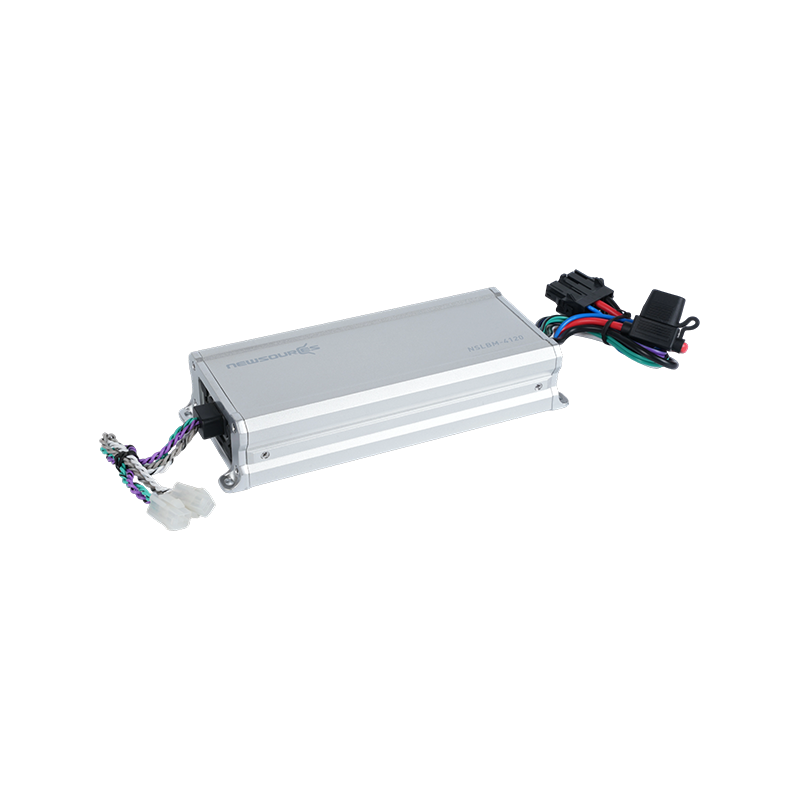

Key Structural Differences Between IPX5 and IPX4-Class Amplifier Designs

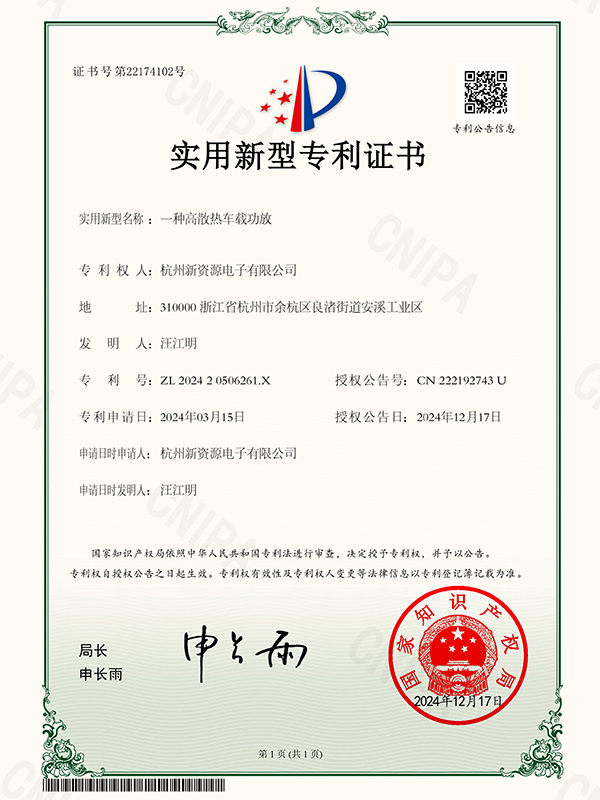

Although both IPX5 and IPX4 Class Powersport Amplifier ratings target outdoor use, the structural engineering behind them differs in water pressure resistance and enclosure sealing. IPX4 designs focus on splash resistance from any direction, often relying on rubberized seals around terminal ports and tight PCB conformal coatings. IPX5 models require stronger sealing systems capable of withstanding direct low-pressure jets, achieved through reinforced gaskets, denser potting materials, and multi-layer enclosure barriers. Manufacturers such as Newsources verify integrity through repeated water jet testing and post-test AP inspections to ensure no moisture penetrates critical circuitry.

Challenges of Maintaining Audio Fidelity in Semi-Sealed IP-Rated Amplifier Housings

IP-rated housings limit ventilation, which can affect both thermal handling and internal electromagnetic noise levels. Engineers must balance protection with audio performance by using low-loss MOSFETs, shielded inductors, and optimized PCB topologies that minimize heat spots in confined spaces. Since internal airflow is restricted, the thermal path is often improved with external fin-type heatsinks and high-conductivity enclosure alloys. Each design choice ensures that even with strict sealing, the amplifier maintains consistent tonal clarity and stable dynamic response in demanding outdoor environments.

Waterproof Connector Technologies Used in IPX4/IPX5 Powersport Amplifiers

Connector systems represent the most vulnerable points in weather-resistant amplifiers. To meet IPX4 and IPX5 Class Powersport Amplifier standards, manufacturers use sealing methods such as molded-over plugs, O-ring compression interfaces, and gasket-protected screw terminals. Marine-grade Deutsch-style connectors are commonly selected for critical signal and power paths due to their ability to maintain connection integrity under vibration and moisture exposure. Below is a reference comparison of connector types:

| Connector Type |

Water Resistance |

Typical Use |

| Molded-Over Plug |

Strong sealing for low-pressure jets |

Power lines & speaker outputs |

| O-Ring Compression |

Highly resistant to splashes and vibration |

Signal input ports |

| Deutsch-Type Connector |

Exceptional sealing & mechanical stability |

Critical interconnects |

Thermal Management Solutions for Amplifiers with High Waterproofing Levels

Achieving IPX4 or IPX5 protection often reduces natural cooling efficiency by limiting open vents or airflow paths. To compensate, designers use thick aluminum housings that double as external heatsinks, along with internal thermal pads that conduct heat away from MOSFETs and driver ICs. In high-power models, spread-spectrum switching reduces thermal concentration by distributing switching losses evenly. The final performance is validated using aging tests under high temperature and humidity cycles, a standard process in production lines like those at Newsources.

Environmental Hazards That IP-Rated Powersport Amplifiers Must Withstand

Outdoor riding environments expose amplifiers to a combination of UV radiation, mud, saltwater, rain, and extreme vibrational stress. IPX4-class amplifiers can endure splashes and moisture from rain and puddles, while IPX5 amplifiers must handle more intensive conditions such as pressure washing or stream crossings. Both types also require protection against corrosion, which is achieved through conformal coatings and rust-resistant external fasteners. Vibration resistance is improved through SMT manufacturing processes, reinforced solder joints, and shock-absorbing mounting plates.

Optimal Installation Practices for Maintaining IP Rating in Real Use

Even a perfectly sealed amplifier can lose its IP protection if installed incorrectly. To preserve IPX4 or IPX5 integrity, mounting surfaces must be flat and stable, preventing enclosure warping that can compromise gasket compression. All cable entry points should be routed downward to minimize water pooling. Installers should avoid overtightening screws around gasket zones, as this can deform seals. For long-term reliability, heat-shrink tubing, UV-resistant cable jackets, and secure vibration-resistant mounts ensure the system remains fully protected throughout rugged outdoor operation.

EN

EN

English

English Español

Español عربى

عربى

.jpg)

.jpg)