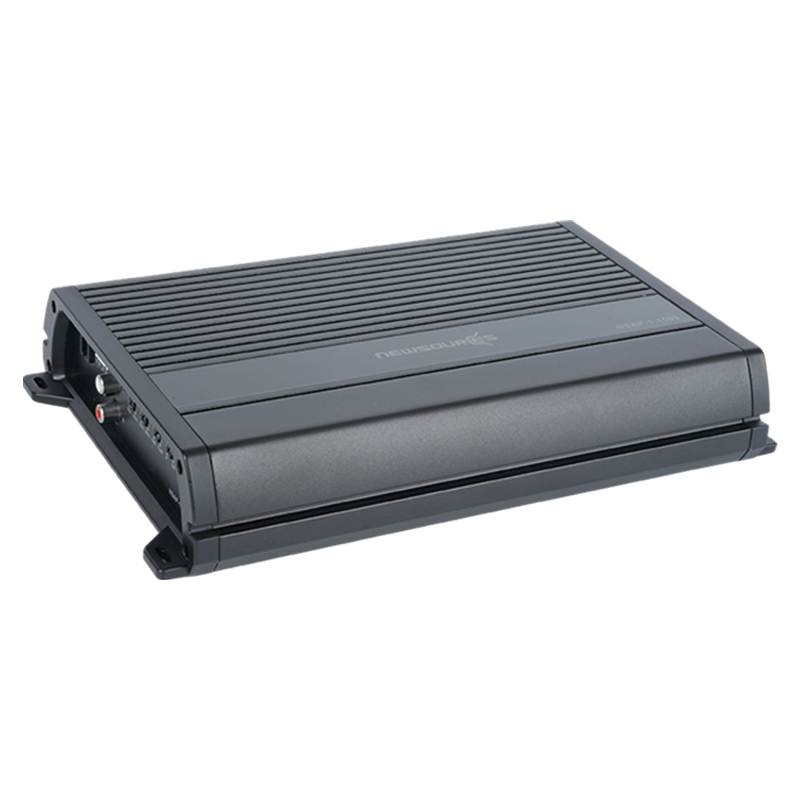

Managing Thermal Density in High-Power Class D Car Amplifiers

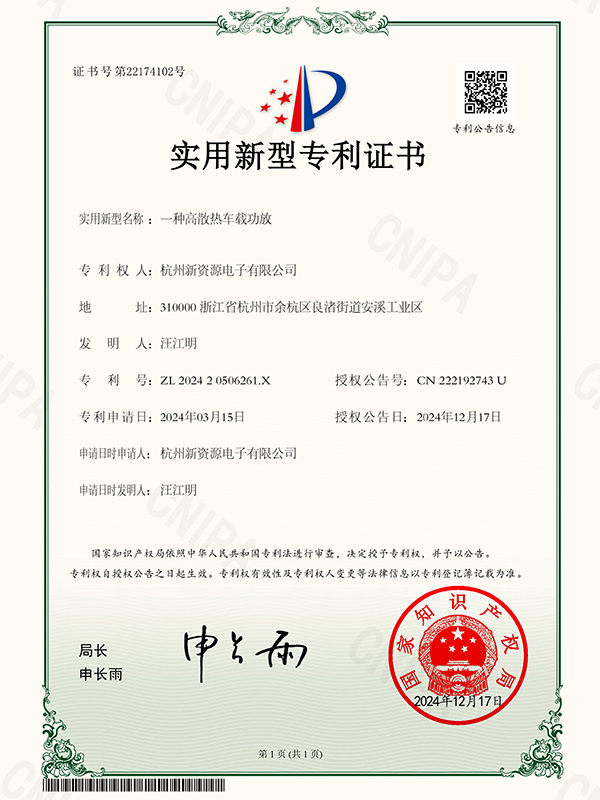

Class D High Power Car Amplifier generate significantly more heat due to higher switching currents and heavier output loads. Effective thermal management requires a combination of multi-layer copper PCBs, optimized MOSFET selection, and expanded heat sink structures. Many high-power models also adopt dual-sided component placement to distribute thermal density more evenly. During production, 100% aging tests conducted under elevated temperatures help reveal thermal runaway risks and ensure stability under continuous high-load operation.

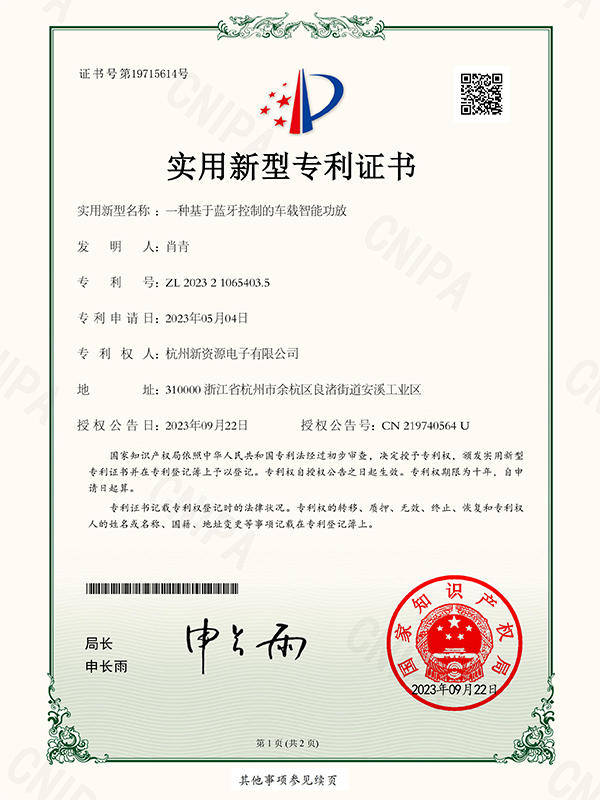

Advanced MOSFET Gate Driving for High-Current Switching

Driving MOSFET gates efficiently is crucial in high-power Class D designs, where switching currents can reach extreme levels. Gate driver ICs must provide rapid rise-and-fall times to minimize switching losses while avoiding excessive ringing. Designers often implement adjustable dead-time control to reduce cross-conduction, especially at higher voltages. Facilities with AP precision testing can tune driver parameters to fine-balance distortions, noise, and thermal output across the full power range.

Common Strategies for Improved Gate Control

- Bootstrap driver circuits for stable high-side gate driving.

- Snubber networks to reduce MOSFET switching spikes.

- Gate resistor tuning to balance EMI and switching speed.

Heavy-Duty Output Inductors and Their Role in High-Power Designs

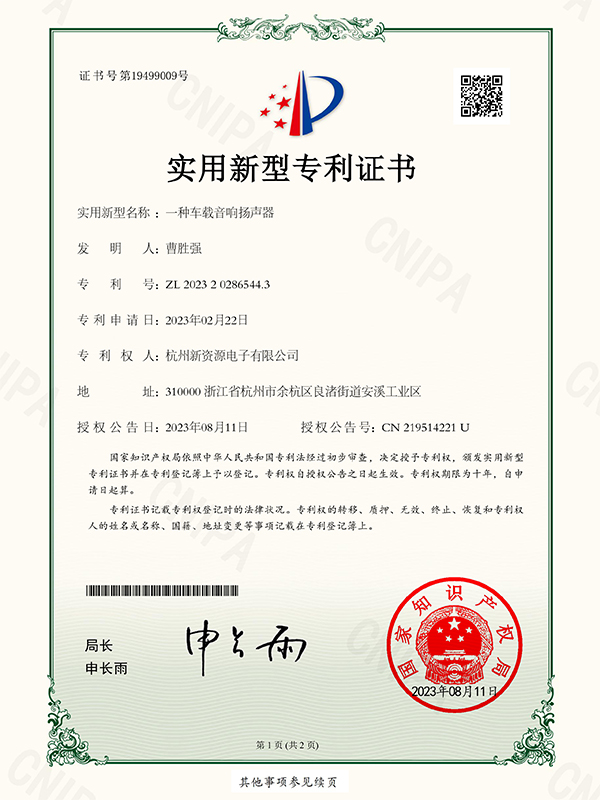

The output inductor must withstand very high currents without saturation or thermal drift. Class D High Power Car Amplifier often use custom-wound inductors with large-core geometries and low-loss materials. Core selection is critical—powdered iron and advanced ferrite composites offer high saturation thresholds. Shielding becomes especially important to prevent interference with nearby vehicle electronics, given the amplifier's elevated magnetic field output under full load.

Inductor Material Comparison for High-Power Applications

| Material |

Key Strengths |

Limitations |

| Powdered Iron |

High saturation, stable at high temp |

Higher core losses at high frequency |

| Ferrite Composite |

Low loss, excellent EMI behavior |

May saturate faster under extreme current |

| Shielded Toroid |

Minimal magnetic leakage |

Typically bulkier and costlier |

Power Supply Stability in High-Power Class D Car Amplifiers

Class D High Power Car Amplifier place massive demands on the vehicle’s electrical system. Designers must ensure that internal DC-DC converters can handle rapid current swings without sagging or excessive ripple. High-frequency transformers, low-ESR capacitors, and multi-layer bus bars are frequently used to support peak output demands. Aging tests with dynamic load cycling are essential for validating the long-term stability of the power stage, especially when the amplifier is installed in vehicles with inconsistent battery conditions.

Controlling EMI Emissions in High-Power Switching Environments

Class D High Power Car Amplifier generate stronger switching edges and electromagnetic fields than lower-power versions, increasing the risk of interference. To comply with automotive EMI standards, designers isolate sensitive input stages, use shielded inductors, and implement multi-pole LC filtering. Proper PCB segmentation—separating high-voltage switching areas from small-signal sections—is essential. Manufacturing consistency provided by AOI inspection and SMT placement ensures stable EMI characteristics across mass production.

Effective EMI Mitigation Techniques

- Use of common-mode chokes in signal and power lines.

- Strategic ground plane partitioning for noise isolation.

- Adding LC filters to attenuate high-frequency switching noise.

Mechanical Reinforcement for High-Vibration Automotive Installations

High-power amplifiers are often installed in areas of the vehicle subject to substantial vibration, such as trunks or under-seat spaces. Mechanical reinforcement ensures long-term reliability. Manufacturers may apply adhesive potting to secure heavy inductors, reinforce transformer mounts, and implement extra PCB standoffs. Robust housing construction using thick aluminum extrusions improves both thermal conductivity and structural stability, ensuring the amplifier withstands years of real-world mechanical stress.

High-Power Audio Performance Optimization Through AP Testing

Achieving clean audio at high output levels requires precise tuning. AP analyzers measure THD+N, channel separation, SNR, and switching noise at multiple power levels. Detailed test curves help engineers identify distortion spikes caused by dead-time misalignment, power supply sag, or inductor saturation. With advanced testing capabilities, manufacturers can maintain consistent high-power performance even across large-scale SMT and wave-soldered production runs.

EN

EN

English

English Español

Español عربى

عربى

.jpg)

.jpg)